ergonomics

Ergonomic hand prothesis for using a drill

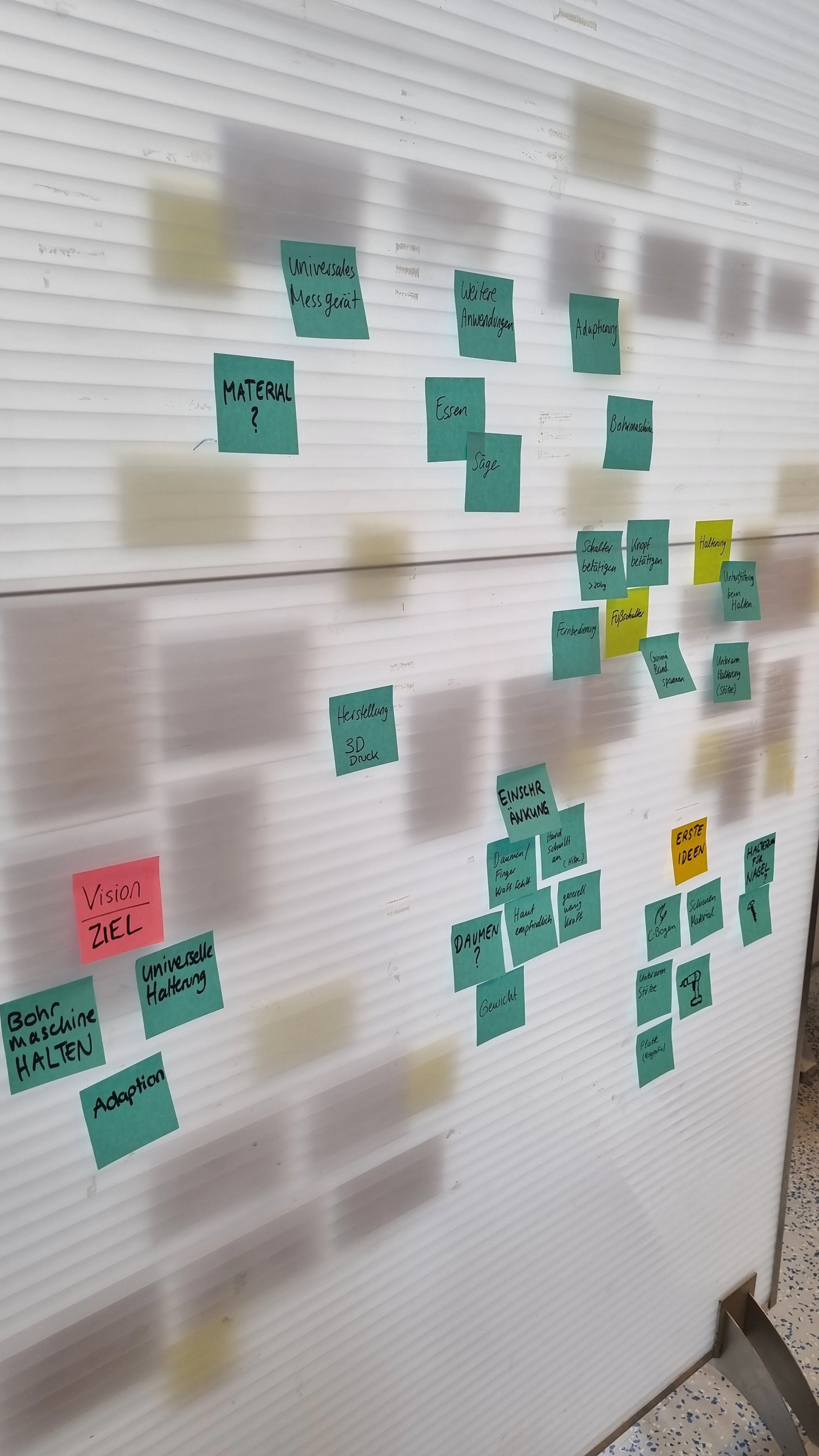

During a two-day workshop at FH Joanneum, industrial design students collaborated with ergonomics students on a special project. Each year, a person with a hand impairment works together with students of these two faculties to explore new ways to enhance their hand functioning. The primary goal of this year's workshop was to enable the person to use a drilling machine, which they are currently unable to use.

Main goal

In this workshop, I served as the team leader for a group consisting of one industrial design student and five ergonomics students. Together, we collaborated to develop an easy yet innovative solution to address the challenge and enhance functionality in the use of a drill.

Achievements

This project was my first time leading a team on my own. I quickly learned to structure the team’s work effectively and employ time management skills to make the most of the limited time we had available. Throughout the process, our primary focus remained on assisting the person as much as possible with our invention. I gained valuable insights into team communication and the importance of rapid prototyping in such projects.

Personal gains

testing phase

final idea

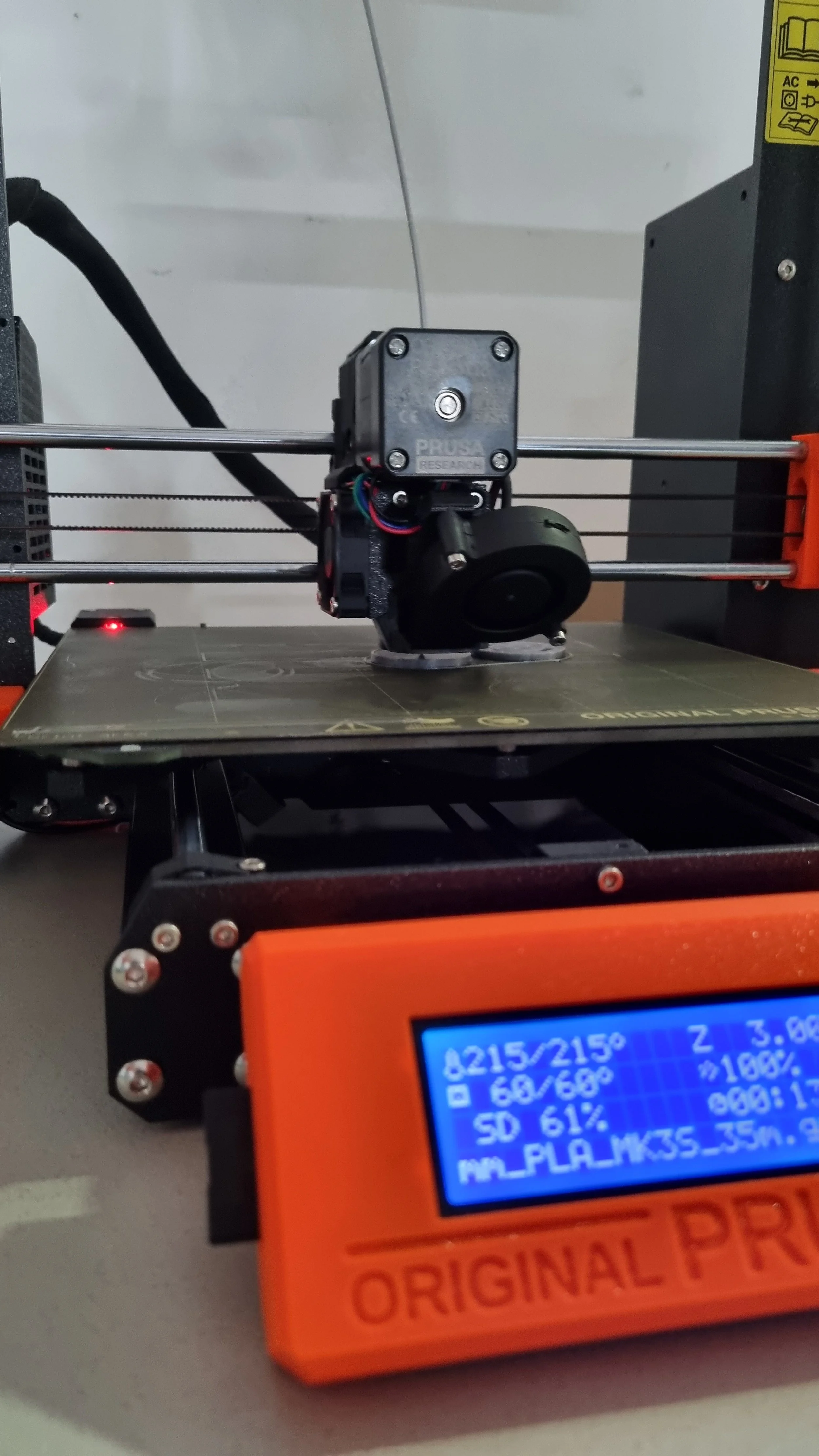

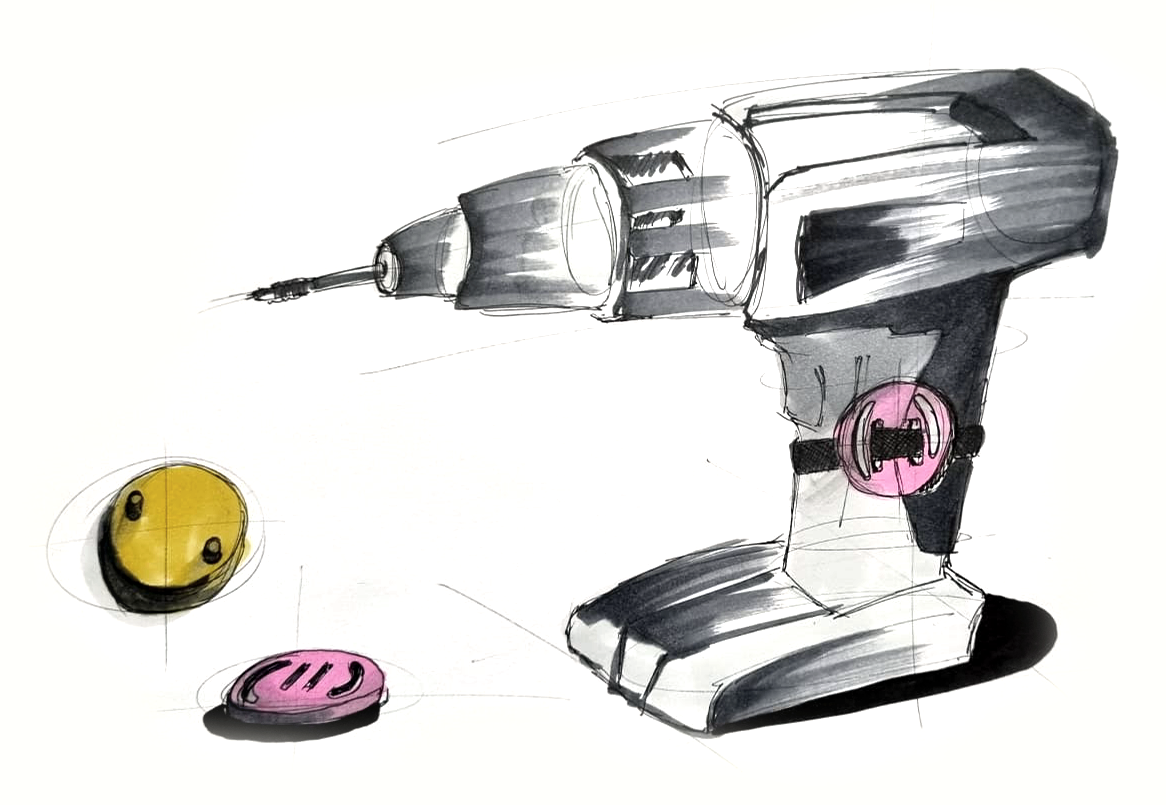

Our final concept involved a clip-in system comprising two parts that seamlessly connect during drill usage and can be quickly detached afterward. We prototyped this idea using 3D-printed parts, integrating ergonomic elements in our design with a plaster prosthesis.